Solar panel efficiency drops when light reflects away from surfaces. Traditional glass wastes precious sunlight through reflection losses. Anti-reflective coating technology transforms solar glass performance dramatically.

Anti-reflective coating for solar glass increases solar transmittance to ≥91.6% by reducing light reflectance, boosting solar cell efficiency by 2-4% while providing self-cleaning properties that maintain long-term performance.

I've witnessed remarkable transformations in solar manufacturing over the past decade. One client's solar panel output jumped 3% immediately after switching to AR-coated glass. These gains translate to significant revenue increases over a panel's 25-year lifespan.

How Does Anti-Reflective Coating Technology Work on Solar Glass?

Solar glass reflection creates energy losses that manufacturers cannot ignore. Understanding the coating mechanism helps optimize production decisions. Smart manufacturers choose coating systems that deliver consistent performance.

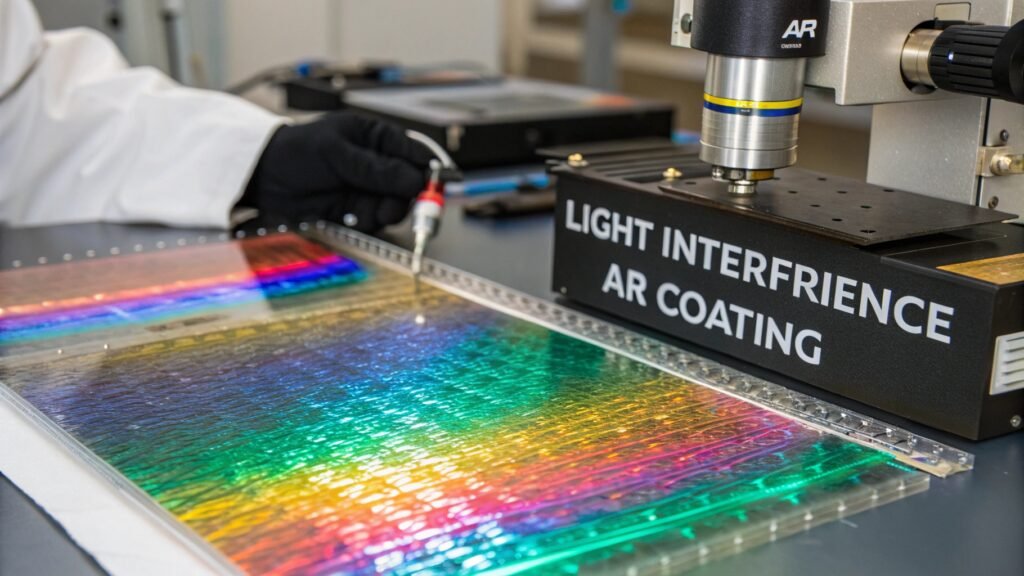

Anti-reflective coatings work by applying thin inorganic films that manipulate incoming light, causing light waves to interfere and cancel each other out, reducing light reflection by more than 75% .

The science behind AR coatings involves precise optical engineering. When light hits the coated surface, the proprietary coating material creates interference patterns that dramatically reduce reflection. This process begins with a thin, inorganic film applied to the glass surface. The coating manipulates light waves so they destructively interfere with reflected light, allowing more energy to pass through to the solar cells.

Technical Specifications for Solar Applications

Solar glass AR coatings must meet demanding performance standards [1]. Low-iron solar glass combined with nanometer anti-reflective coating technology1 achieves solar transmittance levels2 of ≥91.6% for 3.2mm thickness [1]. The coating maintains performance across standard thicknesses of 3.2mm and 4mm with tight tolerances.

Manufacturing specifications require careful attention to detail:

| Parameter | Specification | Impact |

|---|---|---|

| Solar Transmittance | ≥91.6% (3.2mm) | Direct efficiency gain |

| Iron Content | ≤120ppm Fe2O3 | Optical clarity |

| Max Size | 2250mm×3300mm | Production flexibility |

| Thickness Tolerance | ±0.20mm (3.2mm) | Coating uniformity |

The coating process also provides additional benefits beyond optical performance. The super water-wet behavior of the coating protects against dust and dirt accumulation while improving self-cleaning properties. This helps solar panels maintain high efficiency throughout their operational life .

Our photovoltaic glass ARC line demonstrates these principles in commercial production. The system applies AR coatings with precision control to achieve consistent transmittance across large glass panels.

What Manufacturing Benefits Do AR Coatings Provide for Solar Glass Production?

Production efficiency matters as much as optical performance in commercial manufacturing. AR coating systems must integrate smoothly with existing workflows. Understanding these benefits helps justify equipment investments.

AR coating manufacturing reduces reflected glare and environmental pollution while providing self-cleaning properties that decrease maintenance requirements and extend solar panel operational efficiency.

Environmental considerations drive many AR coating3 adoption decisions. The technology reduces reflected glare that can cause visual pollution and environmental concerns. This addresses regulatory requirements in many jurisdictions where solar installations must minimize light pollution impacts on surrounding areas.

Production and Quality Advantages

Manufacturing processes benefit from AR coating3 integration in multiple ways. The coating maintains color fidelity rather than dulling colors like some commercial alternatives. This true-color rendering provides excellent benefits for high-resolution applicationsand ensures consistent product appearance across production runs.

Self-cleaning properties represent a significant operational advantage. The coating's super water-wet behavior helps prevent dust and dirt accumulation that would otherwise shade the solar cells . This translates to reduced maintenance costs and more consistent energy output over the panel's lifetime.

Quality control becomes more predictable with proper AR coating3 systems. Our thin film CdTe PV technology incorporates AR coating3 principles for specialized solar applications. The precision coating application ensures uniform performance across large substrate areas.

Economic Impact Analysis

The economic benefits extend beyond initial efficiency gains:

| Benefit Category | Impact | Timeline |

|---|---|---|

| Efficiency Increase | 2-4% power output gain | Immediate |

| Maintenance Reduction | Lower cleaning frequency | Ongoing |

| Durability Enhancement | Extended panel life | Long-term |

| Environmental Compliance | Reduced glare complaints | Project approval |

Integration with existing production lines requires careful planning. Our automatic glass packing line handles AR-coated glass safely to prevent coating damage during transport and storage.

How Should Manufacturers Select AR Coating Equipment for Solar Glass?

Equipment selection determines long-term production success and profitability. Different coating methods suit various production scales and quality requirements. Making the right choice requires understanding technical and economic factors.

Manufacturers should evaluate coating uniformity, production capacity, and integration capabilities when selecting AR coating equipment, ensuring the system matches their specific solar glass production requirements and quality standards.

Equipment evaluation starts with understanding production requirements. Solar glass manufacturing demands consistent coating thickness4 across large substrates, typically up to 2250mm×3300mm. The coating system must handle these dimensions while maintaining uniformity within tight tolerances.

Critical Selection Factors

Production volume significantly influences equipment choice. High-volume manufacturers need automated systems5 with rapid processing capabilities. Our perovskite material coating and annealing line demonstrates advanced automation principles applicable to AR coating production.

Quality control capabilities matter tremendously in solar applications. The coating system must consistently achieve the required solar transmittance levels. Monitoring systems should verify coating thickness4, uniformity, and optical properties in real-time during production.

Integration considerations affect total system cost and efficiency. The AR coating line must work seamlessly with glass cutting, tempering, and assembly operations. Proper material handling prevents coating damage while maintaining production flow.

Technology Comparison for Solar Applications

Different coating technologies6 offer specific advantages for solar glass production:

| Technology | Uniformity | Speed | Durability | Cost |

|---|---|---|---|---|

| PVD Sputtering | Excellent | Medium | High | High |

| CVD Process | Very Good | Fast | Very High | Medium |

| Sol-Gel Coating | Good | Variable | Medium | Low |

Our experience shows that proper equipment selection pays dividends through reduced maintenance, consistent quality, and higher yields. The initial investment in quality coating equipment typically pays back within 18-24 months through improved product performance and reduced waste.

Training and support become critical success factors. Our technical team provides comprehensive training to ensure operators understand the coating process, quality control procedures, and maintenance requirements. This knowledge transfer prevents costly mistakes and maximizes equipment utilization.

Conclusion

Anti-reflective coating transforms solar glass performance through proven optical science, delivering 2-4% efficiency gains while reducing maintenance requirements and environmental impact through advanced manufacturing technology.

-

Understanding anti-reflective coating technology can enhance your knowledge of solar glass efficiency and its applications. ↩

-

Exploring solar transmittance levels will provide insights into solar panel efficiency and performance standards. ↩

-

Explore how AR coating enhances solar technology by reducing glare and improving efficiency, making it a vital component in modern solar applications. ↩ ↩ ↩ ↩

-

Understanding coating thickness is crucial for achieving optimal performance and efficiency in solar glass production. ↩ ↩

-

Exploring automated systems can reveal how they enhance efficiency and reduce costs in solar glass production. ↩

-

Investigating various coating technologies can provide insights into their advantages and help in making informed equipment choices. ↩