Energy costs keep rising while building standards demand better performance. Traditional glass windows waste energy through heat transfer and UV penetration. Advanced coating machines now solve these challenges with innovative thermal insulation technology.

Glass coating machines apply transparent, thermal insulation, and UV-shielding coatings that achieve 95% infrared/ultraviolet heat insulation while maintaining visibility. These systems can reduce energy consumption by 25%-40% and lower indoor temperatures by 7-15 degrees.

I’ve watched the glass coating industry evolve dramatically over the past decade. When I first started at Glass Coat, basic coatings were the norm. Now I see manufacturers achieving remarkable energy savings with advanced rare earth coating technologies that seemed impossible years ago.

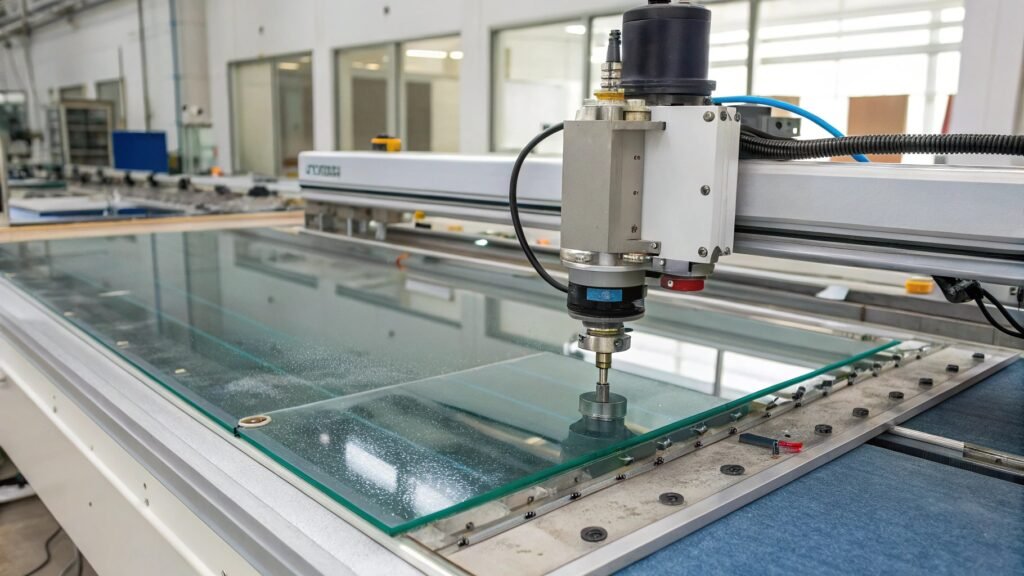

How Do Modern Glass Coating Machines Apply Thermal Insulation Technology?

Energy efficient windows require sophisticated coating application systems. Traditional methods often fail to deliver consistent thermal performance. Understanding the right coating approach determines your project’s success.

Modern glass coating machines utilize rare earth coating (RE coating) technology that innovatively uses nano-rare earth materials to replace traditional ATO and ITO transparent thermal insulation materials, achieving superior performance with 95% heat insulation efficiency.

The breakthrough comes from rare earth materials’ unique electronic structure1 and physical properties. These coatings work fundamentally differently than traditional approaches. Instead of relying on light wave reflection like conventional low-e glass and films, rare earth coatings directly absorb infrared light through the LSP effect2. This converts radiant energy into physical heat energy that air convection removes without affecting visible light transmission.

Technical Advantages Over Traditional Methods

The coating addresses three major pain points of traditional solutions:

- Spectral Selectivity3: Unlike coated metal layers that rely on light wave reflection without spectral selectivity, RE coating provides "targeted" shielding of sunlight while allowing beneficial wavelengths through

- Application Flexibility: The coating can be applied to exterior glass surfaces, unlike films that must be applied indoors where heat exchange becomes difficult

- Durability4: Using principles from stealth fighter absorbing coatings, RE coating maintains stability for 10 years compared to quickly decaying traditional coatings and films

Our glass IR UV shading coating line incorporates these advanced principles. The system applies transparent coatings containing UV/IR blocking nanomaterials using wet coating methods. This achieves significant infrared blocking (>95.5%) and ultraviolet blocking (>94.2%) while maintaining decent visual light transmittance.

The heat transmission science is critical to understand. Glass primarily transfers heat through conduction and radiation. While double-layer glass addresses conduction with air layers, radiation remains problematic. Sunlight spectrum concentrates in 200-2500 nm range, with infrared rays (720-2500 nm) accounting for 50% of total solar energy. Effective infrared blocking without visible light interference dramatically improves glass thermal insulation performance.

What UV Coating Technologies Enhance Window Performance?

UV protection extends beyond thermal comfort to protecting interior spaces and occupants. Poor UV blocking leads to furniture fading and health concerns. Advanced coating machines now integrate UV shielding with thermal insulation.

UV coating systems apply protective layers that block harmful ultraviolet radiation while maintaining transparency. These coatings use automatic spray technology with precise thickness control for consistent performance across large glass surfaces.

Modern UV coating lines incorporate sophisticated application methods. The automatic painting technology includes advanced spray guns that customers can upgrade to full-automatic painting robots. This ensures uniform coating distribution across varying glass sizes and shapes. The water curtain spray design and paint mist recycle system greatly reduces paint mist pollution proliferation.

Process Control Features

Advanced coating systems provide comprehensive process control :

- Chain Type Design: Auto chain systems enable flexible line planning and installation

- Human-Machine Interface: Entirely new interface design with PLC automatic control systems provides simple fingertip operation

- Heating Integration: Reasonable infrared heating arrangement with UV curing layout ensures quick, uniform curing without dead angles

The curing process is particularly critical for glass applications. UV curing equipment includes multiple high-power UV lights with complete UV curing device coverage. This ensures proper coating cross-linking and adhesion to glass surfaces. Temperature control during curing affects both coating properties and glass thermal stress.

Our [photovoltaic glass ARC line](https://glscoat.com/photovoltaic-glass-arc-line/)5 demonstrates how UV coating technology6 integrates with specialized glass applications. The system applies anti-reflective coatings while maintaining UV protection, crucial for solar applications where both light transmission and UV resistance matter.

Quality control requires proper environmental conditions. High-efficiency filters improve purification rates and cleanliness in coating chambers. This prevents contamination that could compromise coating performance or appearance.

How Do Energy Efficient Glass Coating Systems Impact Building Performance?

Building performance depends on integrated window solutions that address multiple environmental factors. Energy costs, comfort, and regulatory compliance all influence coating system selection. Smart building managers evaluate total system benefits.

Energy efficient glass coating systems reduce building energy consumption by 25%-40% while quickly cooling interior temperatures within 3 hours, achieving maximum temperature reductions of 7-15 degrees [1]. This performance far exceeds traditional glass insulation products.

The energy savings7 come from addressing solar heat gain8 comprehensively. Sunlight energy distribution shows ultraviolet accounting for 5% of total energy, visible light 45%, and infrared 50% . By effectively blocking infrared and UV while maintaining visible light transmission, coated glass9 dramatically reduces cooling loads while preserving natural lighting benefits.

Performance Comparison Analysis

Traditional approaches show significant limitations compared to advanced coating systems:

| Technology Type | IR Blocking | UV Blocking | Visible Light Impact | Durability |

|---|---|---|---|---|

| Traditional Solar Film | 30-70% | Variable | Reduced transmission | 2-5 years |

| Low-E Glass | Moderate | Limited | Minimal impact | 5-8 years |

| RE Coating | 95% | 95% | Maintains clarity | 10+ years |

The superior performance creates tangible benefits for building operations. Reduced HVAC loads lower operating costs while improved occupant comfort enhances productivity. Natural light preservation reduces artificial lighting needs during daytime hours.

Our perovskite material coating and annealing line represents next-generation technology for specialized applications. While primarily designed for solar cells, the precision temperature control and uniformity principles apply to architectural glass coating systems.

Environmental benefits extend beyond energy savings7. Reduced cleaning chemical requirements and extended glass lifespan contribute to sustainability goals. The coatings resist environmental degradation better than traditional solutions, maintaining performance throughout their service life.

System integration affects implementation success. Modern coating lines accommodate various glass sizes and production volumes. Our automatic glass packing line ensures proper handling of coated glass9 to prevent damage during transport and installation.

Quality verification requires proper testing protocols. Coating uniformity, adhesion strength, and optical properties need verification before installation. Infrared imaging and spectrophotometry provide objective performance measurements that validate energy efficiency claims.

Conclusion

Glass coating machines enable energy efficient windows through advanced thermal insulation and UV-shielding technology, delivering measurable energy savings and improved building performance with durable, transparent coatings.

-

Understanding the unique electronic structures of rare earth materials can enhance your knowledge of their applications in technology. ↩

-

Exploring the LSP effect will provide insights into how these coatings improve energy efficiency and performance. ↩

-

Understanding Spectral Selectivity can enhance your knowledge of advanced coating technologies and their benefits. ↩

-

Exploring the importance of Durability in coatings will help you appreciate long-lasting solutions in various applications. ↩

-

Discover the innovative features of the photovoltaic glass ARC line and its significance in solar applications. ↩

-

Explore this link to understand how UV coating technology enhances performance and efficiency in various applications. ↩

-

This resource offers insights into effective strategies for maximizing energy savings, essential for sustainable building practices. ↩ ↩

-

Understanding solar heat gain is crucial for optimizing energy efficiency in buildings, making this resource invaluable. ↩

-

Exploring the benefits of coated glass can reveal innovative solutions for reducing energy costs and enhancing comfort. ↩ ↩