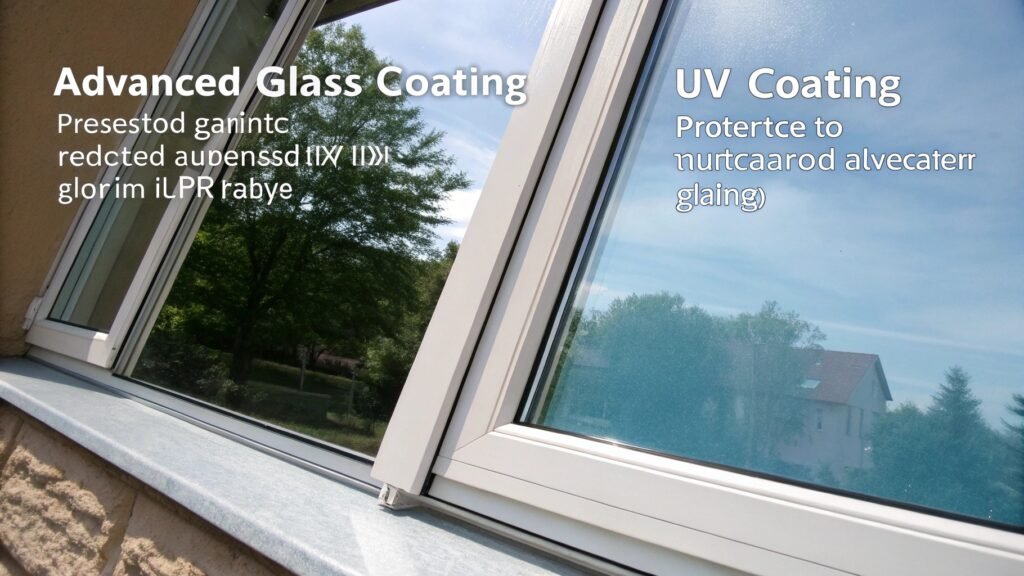

Energy costs spiral upward while building owners struggle with heat gain and UV damage. Traditional window films fail after years while expensive Low-E glass breaks budgets.

Advanced wet-applied glass coatings provide superior IR and UV protection by blocking over 95% of infrared radiation and 94% of ultraviolet rays. These nano-coatings maintain 70%+ visible light transmission, achieve Solar Heat Gain Coefficient below 0.5, and last 15+ years with proper application.

I have spent years developing coating solutions that address the real challenges facing modern architecture. Many building owners invest in expensive glass systems only to discover they still face excessive cooling costs and fading problems. The solution requires understanding how different coating technologies interact with solar radiation and building performance requirements.

How do nano-particle coatings achieve superior solar control performance?

Nano-particle technology creates coatings with precise optical properties. These microscopic particles interact with specific wavelengths while allowing visible light to pass through.

Nano-particle glass coatings use tungsten oxide, indium tin oxide, and silver particles sized 10-50 nanometers to selectively block infrared radiation. They achieve infrared rejection above 95% while maintaining visible light transmission of 73%, creating comfortable indoor environments without sacrificing natural lighting.

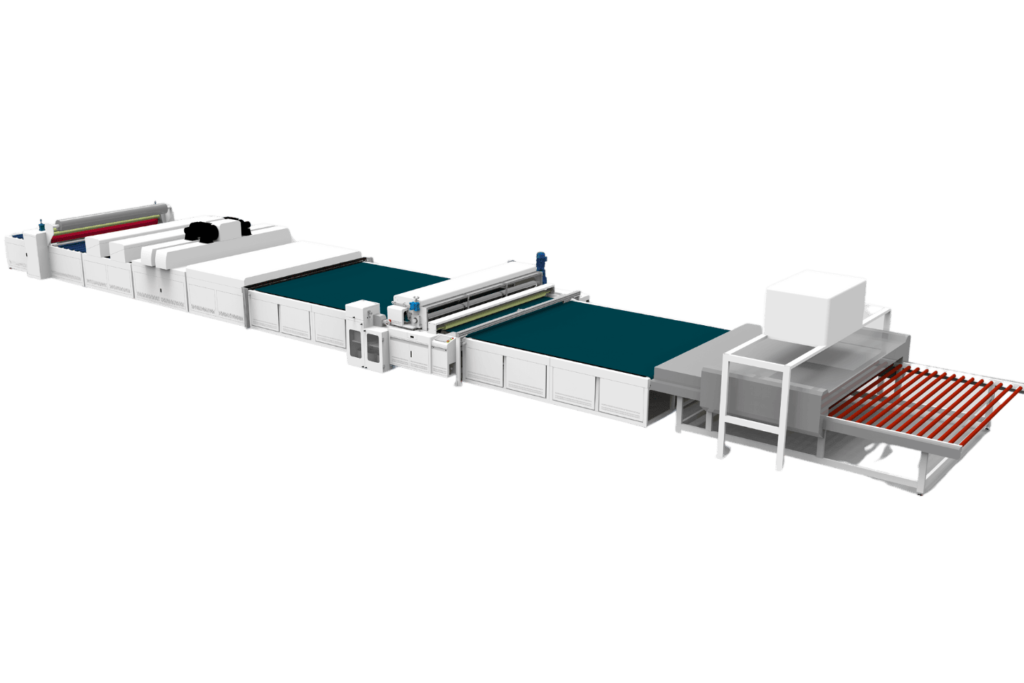

Our IR/UV shading coating line applies these advanced materials with precise thickness control. The coating process requires maintaining particle dispersion and preventing agglomeration that reduces optical performance. Temperature and humidity control during application ensures consistent results across large architectural panels.

The particle size determines wavelength selectivity. Smaller particles interact with shorter wavelengths like UV radiation. Larger particles within the nano-range target infrared wavelengths responsible for heat gain. Multi-layer coatings combine different particle sizes to optimize performance across the entire solar spectrum.

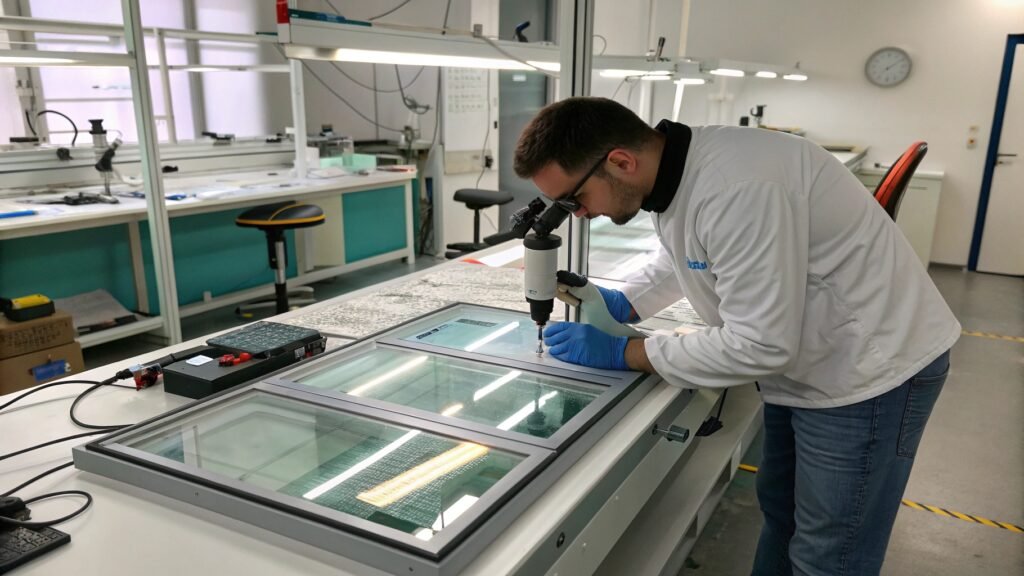

Surface preparation becomes critical for nano-particle adhesion. Glass substrates must achieve cleanliness levels exceeding standard window cleaning. Contamination particles larger than the coating thickness can create defects that compromise performance and durability.

Coating thickness control affects both optical properties and mechanical durability. Thinner coatings may not provide adequate protection while thicker applications can reduce visible light transmission below acceptable levels. Our equipment maintains thickness uniformity within ±5% across panels up to 3.3 meters wide.

| Particle Type | Size Range (nm) | Primary Function | Performance Benefit |

|---|---|---|---|

| Tungsten Oxide | 15-30 | IR Absorption | >90% heat rejection |

| Silver Nano | 5-15 | IR Reflection | >95% heat reflection |

| Titanium Dioxide | 10-25 | UV Blocking | >94% UV protection |

| Indium Tin Oxide | 20-40 | Conductivity | Anti-static properties |

Which wet coating processes deliver the most durable protection?

Wet coating processes create stronger bonds with glass substrates compared to film applications. The liquid coating penetrates surface irregularities and forms chemical bonds during curing.

Wet coating processes using sol-gel chemistry and polymer matrix systems create coatings with adhesion strength exceeding 4H pencil hardness. These processes achieve 15-20 year durability through cross-linked polymer networks that resist weathering, thermal cycling, and mechanical damage while maintaining optical performance.

Sol-gel chemistry forms the foundation of our most durable coating systems. Silicon alkoxide precursors create a glass-like matrix that bonds chemically with the substrate. This process eliminates the interface weakness found in film applications where adhesive failure commonly occurs.

Curing temperature and time control determine final coating properties. Lower temperatures extend curing time but reduce thermal stress in the glass substrate. Higher temperatures accelerate curing but can cause dimensional changes in large panels. Our systems optimize these parameters based on glass thickness and coating chemistry.

Multi-layer application builds up coating thickness while maintaining adhesion between layers. Each layer must cure sufficiently to provide a stable base for subsequent applications. Process timing becomes critical to achieve proper inter-layer bonding without creating interface defects.

Environmental resistance testing verifies long-term performance under real-world conditions. Accelerated weathering tests simulate years of UV exposure, temperature cycling, and humidity changes. Coatings that pass these tests maintain optical properties and adhesion throughout their service life.

Our experience with photovoltaic glass applications demonstrates how proper wet coating processes withstand harsh outdoor environments. The same durability principles apply to architectural applications where coating failure would require expensive replacement procedures.

| Coating System | Cure Temperature | Cure Time | Expected Life | Hardness |

|---|---|---|---|---|

| Sol-Gel Basic | 150°C | 30 min | 10-12 years | 3H |

| Sol-Gel Premium | 180°C | 45 min | 15-18 years | 4H |

| Hybrid Polymer | 120°C | 60 min | 12-15 years | 3H+ |

| Advanced Ceramic | 200°C | 75 min | 18-25 years | 5H+ |

What optical performance specifications matter most for building applications?

Building performance depends on balancing solar control with natural lighting requirements. Understanding key optical metrics helps specify coatings that meet both energy efficiency and occupant comfort goals.

Critical optical specifications include Solar Heat Gain Coefficient below 0.5, visible light transmittance above 65%, and UV transmission below 5%. These values ensure significant cooling load reduction while maintaining adequate daylight and protecting interior materials from UV degradation over decades of service.

Solar Heat Gain Coefficient1 measures total solar energy transmission through the glazing system. Values below 0.5 indicate effective solar control suitable for cooling-dominated climates. Our coatings typically achieve SHGC values between 0.35-0.45 while maintaining good visible light transmission.

Visible Light Transmittance2 determines natural lighting levels inside buildings. Values above 65% prevent the need for excessive artificial lighting during daytime hours. This balance reduces both cooling loads from solar heat gain and lighting energy consumption.

UV transmission below 5% protects interior materials from fading and degradation. Fabrics, carpets, and artwork maintain their appearance longer when UV exposure is minimized. This protection adds significant value for commercial buildings with expensive interior finishes.

Infrared rejection specifically targets wavelengths responsible for heat gain. Near-infrared radiation (700-1400nm) carries substantial thermal energy but contributes nothing to useful lighting. Effective coatings block over 90% of this radiation while allowing visible wavelengths to pass through.

Color rendering properties affect how objects appear under natural light filtering through coated glass. High-quality coatings maintain color neutrality without introducing unwanted tints that distort interior lighting conditions.

| Performance Metric | Minimum Standard | Good Performance | Excellent Performance |

|---|---|---|---|

| SHGC | <0.70 | <0.50 | <0.40 |

| Visible Transmittance | >50% | >65% | >70% |

| UV Transmission | <10% | <5% | <2% |

| IR Rejection | >80% | >90% | >95% |

How do coating applications integrate with existing building systems?

Successful coating implementation requires coordination with building design, HVAC systems, and construction schedules. Integration planning prevents conflicts and maximizes energy performance benefits.

Glass coating integration involves coordinating with glazing contractors, HVAC designers, and building commissioning teams to optimize system performance. Proper integration reduces cooling loads by 25-40%, enables smaller HVAC equipment sizing, and provides payback periods of 3-5 years through energy savings and equipment cost reductions.

HVAC system sizing depends on solar heat gain calculations2 that include glazing performance. Specifying high-performance coatings3 early in design allows engineers to reduce cooling equipment capacity. This equipment downsizing often offsets coating costs while providing ongoing energy savings.

Construction scheduling must account for coating cure times and quality control requirements. Rush installations compromise coating quality and long-term performance. Our experience shows that proper scheduling prevents costly delays while ensuring optimal results.

Building orientation and local climate conditions affect coating specification requirements. South-facing windows in cooling climates benefit from maximum solar rejection. North-facing windows may prioritize visible light transmission over solar control. East and west orientations require balanced performance for morning and afternoon sun angles.

Integration with automated shading systems provides additional control over solar heat gain and glare. Smart building systems can coordinate motorized shades with coating performance to optimize comfort and energy efficiency throughout the day.

Our decorative glass coating solutions demonstrate how functional coatings integrate with architectural aesthetics. The combination provides both energy performance and visual appeal without compromising either objective.

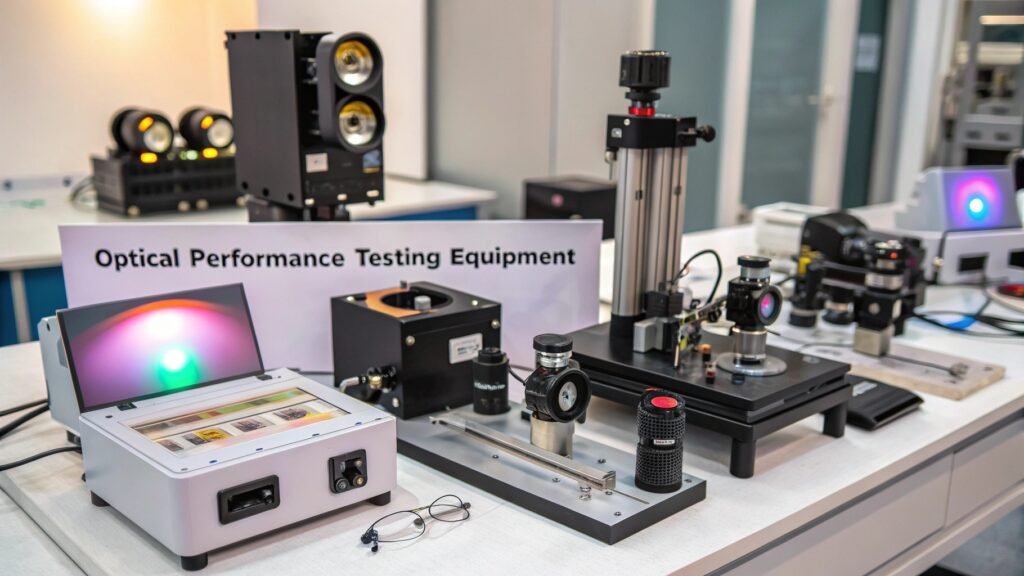

Which quality control measures ensure consistent coating performance?

Coating quality affects both immediate optical performance and long-term durability. Comprehensive quality control prevents field failures that would require expensive remediation.

Quality control for architectural glass coatings includes spectral transmission measurement, adhesion testing, environmental simulation, and statistical process monitoring. These measures achieve coating uniformity within ±3% across large panels while ensuring 99.5% adhesion test pass rates and performance retention above 95% after 20 years of simulated weathering.

Spectral measurement verifies optical properties across the entire solar spectrum. Laboratory-grade spectrophotometers4 measure transmission and reflection at hundreds of wavelengths. This data confirms that coatings meet specified performance criteria before installation.

Adhesion testing uses standardized methods including cross-cut tests and pull-off measurements. Coatings must achieve minimum adhesion values to survive thermal cycling and wind loads over their service life. Our testing protocols exceed industry standards to ensure long-term reliability.

Environmental simulation subjects coating samples to accelerated weathering conditions. UV exposure, temperature cycling, humidity changes, and salt spray testing reveal potential durability issues before they affect building performance. These tests predict 20+ year performance based on weeks of laboratory exposure.

Process monitoring tracks coating application parameters in real-time. Temperature, humidity, coating thickness, and curing profiles are recorded for each panel. This data enables rapid problem identification and ensures consistent results across entire building projects.

Our quality systems developed for advanced solar applications provide the precision needed for architectural coatings. The same attention to process control ensures reliable performance in building environments.

| Test Parameter | Measurement Method | Accept/Reject Criteria | Test Frequency |

|---|---|---|---|

| Optical Properties | Spectrophotometry | ±3% of specification | Every panel |

| Coating Thickness | Cross-section analysis | ±10% of target | 1 per 100 panels |

| Adhesion Strength | Cross-cut test | Grade 0-1 acceptable | 1 per 50 panels |

| Durability | Accelerated weathering | <5% change after 2000h | Per coating batch |

Conclusion

Advanced glass coatings deliver superior energy performance through nano-particle technology, durable wet coating processes, and integrated building system design that reduces energy costs while maintaining occupant comfort.

-

Understanding SHGC is crucial for optimizing energy efficiency in buildings, especially in cooling-dominated climates. ↩

-

Understanding solar heat gain calculations is crucial for optimizing HVAC systems, ensuring energy efficiency and comfort in buildings. ↩ ↩

-

Exploring high-performance coatings can reveal their role in reducing energy costs and enhancing the longevity of HVAC systems. ↩

-

Explore this link to discover top-rated spectrophotometers that ensure accurate optical measurements for your projects. ↩