Are you wondering how glass manufacturing is evolving to meet decarbonization goals? Well, you're not alone. The push for a greener future is reshaping industries, and glass manufacturing is no exception. As the CEO of GlassCoat, I’ve had a front-row seat to the innovations in glass manufacturing equipment and the technologies driving decarbonization. Let me break it down for you.

In short, glass manufacturing is undergoing a transformation, focusing on efficiency and sustainability. New technologies, including advanced glass coating machinery, low-emissivity (Low-E) coatings, and UV protective glass coatings, are at the heart of this shift. These innovations are not just reducing emissions but also enhancing the functionality of glass products.

Why should you care? Because the future of glass manufacturing is all about cutting carbon footprints while meeting modern architectural and environmental needs. Let’s dig deeper into how this is happening.

What is Glass Manufacturing Equipment and How is it Evolving?

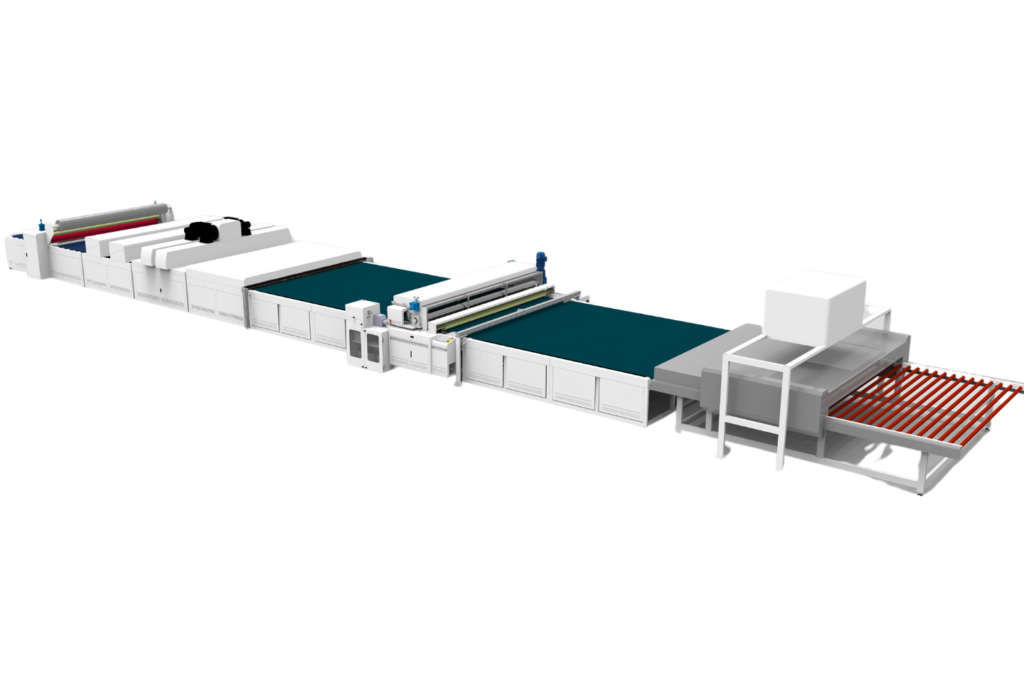

Glass manufacturing equipment has come a long way from traditional furnace and molding machines. Nowadays, we see smart technology, automation, and precision engineering taking over. These advancements have significantly improved efficiency, reducing energy consumption and emissions. But what makes modern glass manufacturing equipment special?

Think about glass processing machinery that can handle more complex designs, thinner and stronger glass sheets, and intricate coatings. And let’s not forget the role of cutting-edge glass coating machines that apply specialized coatings like Low-E and UV protective layers with incredible precision.

So, how does all this help with decarbonization? The answer is simple: less waste, less energy, and more sustainable practices.

How Do Glass Coating Technologies Contribute to Sustainability?

Glass coatings are where things really get exciting. Technologies like low-emissivity glass coating and UV protective glass coating are game-changers for energy efficiency. Low-E coatings reflect heat while allowing light to pass through, helping to keep buildings cooler in summer and warmer in winter. This reduces the need for heating and cooling, cutting down on energy use and emissions.

On the other hand, UV protective glass coatings block harmful ultraviolet rays while allowing visible light to enter. This is great for reducing fading of interior furnishings and provides an additional layer of energy efficiency by controlling heat gain.

But here’s the kicker: these coatings are applied using state-of-the-art glass coating equipment that minimizes material waste and ensures a consistent finish. This level of precision reduces the need for rework and ensures maximum performance from every piece of glass.

Can These Innovations Really Cut Carbon Emissions in the Glass Industry?

Absolutely. In fact, we’ve already seen a significant impact. The U.S. Department of Energy (DOE) recently announced a Glass Decarbonization Workshop, where industry leaders gathered to discuss how new technologies can reduce carbon footprints across the glass supply chain. It’s clear that the future of glass manufacturing is green.

By embracing advanced glass processing machinery and glass coating machines, manufacturers are able to cut down on the high energy demands that have historically plagued the industry. When you consider the energy savings from using Low-E and UV protective coatings in buildings, the overall carbon reduction is even more impressive.

What Are Some of the Challenges in Adopting These Technologies?

Let’s be real—no innovation comes without challenges. Adopting new glass coating technologies and machinery involves a significant investment. Many manufacturers are still figuring out how to integrate these tools into their existing systems without disrupting production or increasing costs.

1.Canoldermanufacturingplantsretrofittheirequipment?2.What’stheupfrontcostofinstallingnewglasscoatingmachines?3.Willtheindustryseeareturnoninvestmentfromthesesustainabilityupgrades?4.Howdoweensurethatallpartsofthesupplychainadoptdecarbonizationpractices?5.Cansmallerglassmanufacturersaffordtoadoptthesenewtechnologies?6.Howlongbeforeweseeasignificantreductioninemissionsindustry-wide?

These are the questions that we, as industry leaders, are constantly evaluating. But here’s the good news: government incentives and industry grants are available to help offset some of these costs.

The Role of Industry Associations in Promoting Decarbonization

Industry associations like the National Glass Association (NGA) and the Glass Manufacturing Industry Council (GMIC) are playing a pivotal role in promoting decarbonization. They are actively lobbying for expanded tax credits and government support for high-performance glass technologies, including glass coating equipment and low-emissivity glass coatings.

For example, the NGA is pushing for an expansion of the Section 48 investment tax credit, which would allow more types of dynamic glass, such as triple glazing and vacuum-insulated glazing, to qualify for incentives. This would open the door for more manufacturers to adopt these energy-efficient solutions.

What’s Next for Glass Coating Technology?

I believe we’re only scratching the surface when it comes to glass coating technology. The next big frontier could be self-cleaning glass coatings, which could further reduce maintenance costs and energy usage. Innovations like these, combined with ongoing improvements in glass processing machinery, will continue to drive decarbonization efforts across the industry.

Imagine a future where every skyscraper, office building, and home is outfitted with high-performance glass that not only saves energy but actively contributes to a sustainable environment. With the right glass coating machines and glass manufacturing equipment, that future isn’t far off.

Final Thoughts: Why Should You Care About Glass Decarbonization?

In my view, decarbonization isn’t just a buzzword—it’s a necessity. The glass industry has a unique opportunity to lead the way in reducing emissions while improving the quality and functionality of its products. By investing in the latest glass manufacturing equipment, glass coating technologies, and sustainable practices, we’re creating a win-win scenario for both the environment and the bottom line.

And hey, if you’re a building owner or architect looking for energy-efficient solutions, keep an eye on innovations in low-emissivity glass coatings and UV protective glass coatings. These technologies are not just the future of glass—they’re the future of sustainable construction.