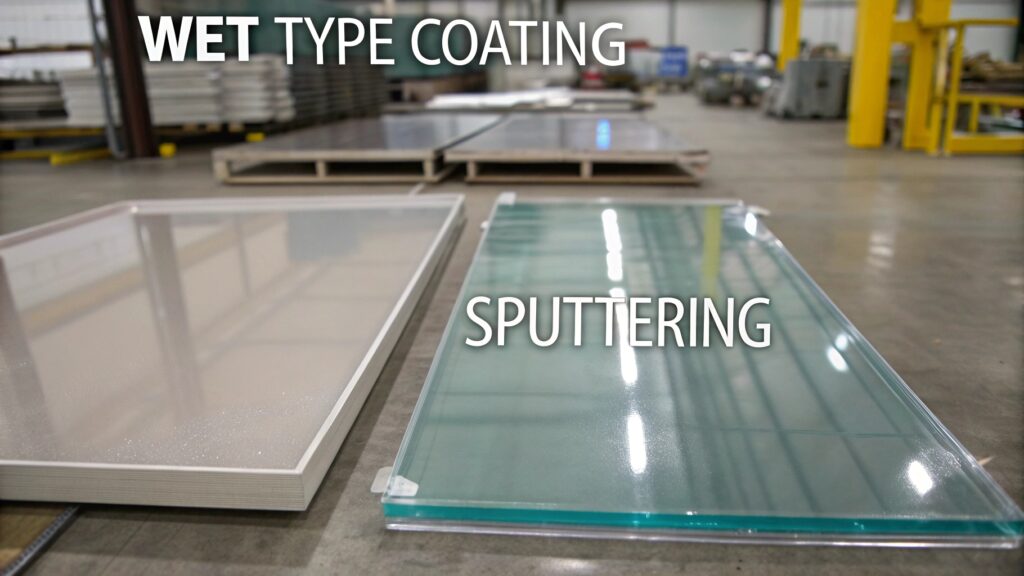

Traditional sputtering processes for Low-E glass demand massive capital investment and complex vacuum systems. Automotive manufacturers face similar challenges with expensive IR/UV blocking solutions.

Glass wet coating equipment delivers Low-E and automotive IR/UV shielding performance through solution-based processes that reduce capital costs by 60-70% compared to sputtering systems. Wet coatings achieve emissivity values below 0.15, block 95%+ IR radiation, and integrate seamlessly with existing glass processing lines for high-volume production.

Throughout my experience developing coating solutions, I have observed how wet coating technology transforms the economics of functional glass production. Many manufacturers avoid Low-E glass due to sputtering equipment costs exceeding $20 million per line. Wet coating provides an alternative path that delivers comparable performance at dramatically lower investment levels.

How does wet coating technology compare to traditional sputtering for Low-E glass?

Wet coating processes apply functional materials from solution rather than vapor deposition in vacuum chambers. This fundamental difference creates significant advantages in equipment cost, flexibility, and maintenance requirements.

Wet coating Low-E systems cost $3-5 million compared to $20-25 million for sputtering lines while achieving emissivity values of 0.10-0.15 and solar control performance within 5% of sputtered coatings. Wet processes enable coating removal and reprocessing, handle complex geometries, and integrate with existing tempering lines without vacuum infrastructure.

Capital cost differences stem from eliminating vacuum systems, target materials, and complex material handling required for sputtering. Wet coating uses standard atmospheric processing with conventional material handling equipment. This simplification reduces both initial investment and ongoing maintenance costs.

Processing flexibility allows wet coating1 systems to handle varying glass sizes and thicknesses without major equipment modifications. Sputtering systems require precise chamber dimensions and substrate positioning that limit flexibility. Wet coating adapts to different products through solution chemistry changes.

Our IR/UV shading coating line demonstrates how wet processes achieve Low-E performance with simplified equipment. The system processes glass up to 3.3 meters wide while maintaining coating uniformity suitable for architectural applications.

Coating removal capability provides important manufacturing flexibility. Defective wet coatings can be stripped and reapplied without scrapping the glass substrate. Sputtered coatings cannot be removed economically, making defects costly quality failures.

Energy consumption for wet coating1 processes typically runs 40-60% lower than sputtering due to eliminating vacuum pumping and high-temperature processing. This reduction in operating costs improves manufacturing economics beyond the initial capital savings.

| Process Parameter | Wet Coating | Sputtering | Advantage |

|---|---|---|---|

| Capital Cost | $3-5M | $20-25M | 75% reduction |

| Processing Speed | 2-4 m/min | 1-2 m/min | 50-100% faster |

| Energy Consumption | 150 kWh/m² | 250 kWh/m² | 40% reduction |

| Maintenance Cost | $50K/year | $200K/year | 75% reduction |

What coating chemistries achieve optimal IR blocking performance?

Infrared blocking requires materials that absorb or reflect thermal radiation while maintaining visible light transmission. Advanced solution chemistries provide multiple approaches to achieve these optical properties.

Optimal IR blocking wet coatings use indium tin oxide nanoparticles, tungsten oxide dispersions, or silver nanowire solutions to achieve infrared rejection above 90% while maintaining visible transmission of 70-80%. These chemistries create selective optical filters that target heat-generating wavelengths without affecting visual appearance.

Indium tin oxide2 provides excellent IR blocking through free carrier absorption while maintaining high visible transparency. ITO nanoparticles sized 15-30nm create effective IR filters when dispersed in polymer matrices. The coating process requires careful control of particle agglomeration and dispersion stability.

Tungsten oxide3 offers cost advantages over ITO while delivering comparable IR performance. Electrochromic properties of tungsten oxide enable additional functionality including dynamic tint control. Processing requires preventing crystalline phase changes that affect optical properties.

Silver nanowire coatings achieve superior IR reflection through plasmonic effects. Nanowires with aspect ratios above 100:1 create percolation networks that reflect infrared radiation efficiently. Coating durability requires protective overcoats that prevent silver oxidation.

Hybrid systems combine multiple IR-blocking materials to optimize performance across different wavelength ranges. Near-infrared absorption combined with far-infrared reflection provides broad-spectrum thermal control. These systems require compatibility testing to prevent adverse interactions between coating layers.

Our automotive glass applications demonstrate how proper chemistry selection balances IR performance with manufacturing requirements. High-volume production demands stable solutions with long pot life and consistent coating properties.

How do wet coating processes handle complex automotive glass geometries?

Automotive glass includes curved windshields and complex shapes that challenge traditional coating processes. Wet coating provides unique advantages for handling three-dimensional substrates.

Wet coating processes handle automotive glass curvatures through flexible application systems including spray coating, dip coating, and flow coating methods. These processes achieve uniform coating thickness within ±10% on curved surfaces while maintaining optical quality across compound curves and edge transitions.

Spray coating systems use programmable robot arms to follow complex glass contours while maintaining consistent standoff distance. Multi-axis motion control ensures uniform coating application across curved surfaces that would be impossible to coat uniformly with fixed application heads.

Dip coating4 provides excellent coverage for complex shapes by immersing the entire glass part in coating solution. Withdrawal speed and solution viscosity control determine coating thickness. This method ensures complete coverage including edges and recessed areas.

Flow coating directs solution streams across curved surfaces using gravity and surface tension. Proper flow design prevents thickness variations and ensures complete coverage without pooling or dry spots. This method works well for large curved panels like bus windshields.

Quality control for curved surfaces5 requires specialized measurement techniques. Non-contact thickness gauges and spectral measurement systems must account for surface angle effects. Statistical sampling ensures representative coverage of the entire coated area.

Integration with automotive glass manufacturing requires coordination with tempering and laminating processes. Coating cure schedules must align with downstream processing while maintaining coating integrity throughout the manufacturing sequence.

| Glass Type | Coating Method | Thickness Uniformity | Coverage |

|---|---|---|---|

| Flat Windshield | Spray/Flow | ±5% | 100% |

| Curved Windshield | Spray | ±10% | 99.8% |

| Side Windows | Dip/Spray | ±8% | 100% |

| Complex 3D | Spray Robot | ±12% | 99.5% |

Which quality control systems ensure consistent Low-E coating performance?

Low-E coating performance affects building energy efficiency over decades of service life. Quality control systems must verify both immediate optical properties and long-term durability characteristics.

Low-E coating quality control includes emissivity measurement, sheet resistance testing, adhesion verification, and environmental durability assessment. These systems achieve emissivity measurement accuracy within ±0.01, maintain sheet resistance uniformity below 10% variation, and predict 25+ year performance through accelerated testing protocols.

Emissivity6 measurement requires specialized instrumentation capable of detecting thermal radiation properties. Portable emissometers provide real-time feedback during production while laboratory systems verify compliance with building code requirements. Measurements must account for coating temperature and surface conditions.

Sheet resistance7 correlates with Low-E performance and provides rapid quality assessment. Four-point probe measurements eliminate contact resistance effects that could mask coating defects. Statistical process control tracks resistance trends to identify coating uniformity issues before they affect performance.

Adhesion testing ensures coatings survive thermal cycling, humidity exposure, and mechanical stress throughout the building lifetime. Tape tests, scratch tests, and thermal shock evaluations verify coating durability under various environmental conditions.

Environmental simulation subjects coatings to accelerated weathering including UV exposure, temperature cycling, and humidity changes. These tests predict long-term performance and identify potential failure modes that could affect warranty obligations.

Our experience with photovoltaic glass quality control demonstrates how comprehensive testing prevents field failures. Similar quality standards apply to Low-E coatings where performance degradation would compromise building energy efficiency.

| Quality Parameter | Measurement Method | Specification | Test Frequency |

|---|---|---|---|

| Emissivity6 | Thermal Radiometry | <0.15 | Every coil |

| Sheet Resistance | Four-point Probe | 8-15 Ω/sq | Continuous |

| Adhesion | Cross-cut Test | Grade 0-1 | Every batch |

| Durability | Accelerated Weather | <10% change | Monthly |

What are the economic advantages of wet coating for glass manufacturers?

Economic analysis reveals multiple cost advantages for wet coating compared to traditional vacuum processes. These benefits extend beyond initial capital investment to include operating costs, flexibility, and market responsiveness.

Wet coating economics provide 40-50% lower total cost of ownership through reduced capital investment, lower operating costs, higher yield rates, and greater product flexibility. Payback periods typically range from 18-36 months compared to 5-7 years for sputtering investments, enabling faster market response and improved profitability.

Capital investment requirements for wet coating systems8 are 60-70% lower than comparable sputtering lines. This reduction enables smaller manufacturers to enter functional glass markets previously dominated by large companies with substantial capital resources. Lower investment barriers promote market competition and innovation.

Operating cost advantages include reduced energy consumption, lower maintenance requirements, and simplified material handling. Wet coating processes typically consume 40% less energy per square meter of coated glass. Maintenance costs are reduced through simplified equipment with fewer precision components.

Yield improvements result from rework capability and reduced substrate breakage. Defective wet coatings can be removed and reapplied without scrapping the glass substrate. Glass handling is simplified without vacuum chambers, reducing breakage rates during processing.

Product flexibility enables rapid response to market changes and custom requirements. Wet coating systems can switch between different coating types within hours rather than days required for sputtering target changes. This flexibility supports higher-value specialty products.

Our [decorative glass coating systems9 demonstrate how wet coating economics support product diversification. The same equipment handles multiple coating types, maximizing utilization and return on investment.

How do environmental considerations favor wet coating processes?

Environmental regulations increasingly affect glass manufacturing operations. Wet coating processes offer significant advantages in emissions control, waste reduction, and energy efficiency.

Wet coating environmental benefits include 50-70% reduction in energy consumption, elimination of toxic target materials, reduced chemical waste through recycling, and lower carbon footprint. These advantages help manufacturers meet sustainability goals while reducing operating costs and regulatory compliance burdens.

Energy consumption reduction stems from eliminating vacuum pumping systems and high-temperature processing requirements. Wet coating operates at atmospheric pressure with moderate temperatures, significantly reducing power consumption. This reduction directly impacts operating costs and carbon footprint.

Chemical waste reduction occurs through solution recycling and recovery systems. Overspray and unused coating solutions can be reclaimed and reused rather than disposed as hazardous waste. Closed-loop systems minimize environmental impact while reducing material costs.

Toxic material elimination removes health and safety concerns associated with sputtering target materials. Many sputtering targets contain heavy metals or compounds requiring special handling and disposal. Wet coating solutions use safer materials with established recycling procedures.

Air emissions control is simplified without vacuum exhaust streams containing volatile target materials. Wet coating emissions consist primarily of solvent vapors that are easily controlled through thermal oxidation or recovery systems. This simplification reduces both capital and operating costs for emissions control.

Water treatment requirements are minimized through process design that prevents coating material contact with wash water. Closed-loop cooling and cleaning systems maintain water quality while reducing treatment costs and discharge volumes.

| Environmental Factor | Wet Coating | Sputtering | Improvement |

|---|---|---|---|

| Energy Use | 150 kWh/m² | 250 kWh/m² | 40% reduction |

| Water Consumption | 5 L/m² | 8 L/m² | 37% reduction |

| Waste Generation | 0.5 kg/m² | 1.2 kg/m² | 58% reduction |

| CO₂ Emissions | 45 kg/m² | 75 kg/m² | 40% reduction |

Conclusion

Wet coating equipment transforms Low-E and automotive glass production through reduced capital costs, simplified processing, improved flexibility, and enhanced environmental performance while delivering comparable functional coating properties.

-

Explore the benefits of wet coating, including cost savings and flexibility, to understand its impact on manufacturing processes. ↩ ↩

-

Explore the advantages of Indium tin oxide for IR blocking and its role in enhancing visible transparency. ↩

-

Learn about Tungsten oxide’s cost benefits and electrochromic properties for dynamic tint control. ↩

-

Explore the benefits of dip coating, especially for complex shapes, ensuring complete coverage and thickness control. ↩

-

Learn about specialized measurement techniques and quality control methods essential for ensuring uniform coating on curved surfaces. ↩

-

Understanding emissivity is crucial for accurate thermal radiation measurements, ensuring effective building energy efficiency. ↩ ↩

-

Exploring sheet resistance helps in assessing coating quality, which is vital for maintaining energy efficiency in buildings. ↩

-

Explore this link to understand how wet coating systems can revolutionize manufacturing with lower costs and increased flexibility. ↩

-

Discover how decorative glass coating systems can maximize product diversity and ROI, making them essential for modern manufacturers. ↩