Glass cutting and routing demand precision that can make or break your production line. One mistake costs thousands in wasted materials and delayed orders.

The best flat glass cutting machines include waterjet cutters, laser cutting systems, and CNC glass routers with diamond-tipped tools. These machines offer precision cuts from 0.1mm tolerance, handle various glass thicknesses, and integrate with automated production lines for maximum efficiency.

After ten years of designing glass coating equipment, I have seen how the right cutting technology transforms production efficiency. Many manufacturers struggle with glass breakage and poor edge quality. The solution lies in choosing machines that match your specific glass processing needs.

Which waterjet cutting systems deliver the best results for glass?

Waterjet technology creates clean cuts without thermal stress. Your glass stays intact during the entire cutting process.

Waterjet systems use high-pressure water mixed with abrasive particles to cut glass up to 200mm thick. They achieve ±0.1mm precision, produce smooth edges without micro-fractures, and handle tempered, laminated, and specialty glass types effectively.

The top waterjet systems feature multi-axis cutting heads that handle complex shapes. Flow International and OMAX lead the market with systems that cut architectural glass panels up to 4000mm x 2000mm. These machines integrate with our glass coating production lines for seamless workflow.

I worked with a customer who switched from manual cutting to waterjet technology1. Their material waste dropped from 15% to under 3%. The investment paid back within eighteen months through reduced material costs and faster production cycles.

Key specifications to consider include cutting speed2, maximum thickness capacity, and edge quality. Premium systems offer cutting speed2s up to 500mm per minute on 10mm glass. They maintain consistent quality across different glass compositions and surface treatments.

| Feature | Entry Level | Professional | Industrial |

|---|---|---|---|

| Max Thickness | 50mm | 100mm | 200mm |

| Cutting Speed | 200mm/min | 350mm/min | 500mm/min |

| Precision | ±0.25mm | ±0.15mm | ±0.1mm |

| Table Size | 2000x1000mm | 3000x2000mm | 4000x2000mm |

How do laser cutting machines compare for glass processing applications?

Laser systems offer speed advantages for thin glass applications. The focused beam creates precise cuts with minimal material removal.

CO2 and fiber lasers cut glass from 0.5mm to 25mm thickness with cutting speeds up to 15 meters per minute. They excel at intricate patterns, small holes, and complex geometries while maintaining ±0.05mm accuracy on thin substrates.

Trumpf and Bystronic manufacture leading laser systems for glass processing. These machines handle decorative glass applications where intricate patterns and fine details are essential. The laser beam creates clean edges without secondary finishing operations.

Temperature control becomes critical during laser cutting. The focused beam generates heat that can cause thermal stress and cracking. Advanced systems use controlled cooling and optimized cutting parameters to minimize these effects.

Fiber lasers work well for ultra-thin glass substrates used in electronics and solar applications. CO2 lasers handle standard architectural glass more effectively. The choice depends on your glass thickness range and required cutting quality.

Processing speed varies significantly based on glass type and thickness. Clear float glass cuts faster than low-iron or coated glass. Tempered glass requires special consideration due to its internal stress patterns.

| Laser Type | Best Applications | Max Thickness | Typical Speed |

|---|---|---|---|

| CO2 Laser | Architectural glass | 25mm | 3-8 m/min |

| Fiber Laser | Thin substrates | 5mm | 8-15 m/min |

| UV Laser | Precision cutting | 2mm | 1-3 m/min |

What CNC routing capabilities work best for glass edge processing?

CNC routers handle edge finishing and complex shape creation. Diamond-tipped tools provide the durability needed for glass processing.

CNC glass routers use diamond-coated bits to machine edges, drill holes, and create complex profiles. They achieve surface finishes down to Ra 0.8μm, handle glass thickness from 3mm to 50mm, and integrate grinding, polishing, and drilling operations.

Heian and Bavelloni produce specialized CNC systems for glass processing. These machines complement our architectural glass coating lines by providing finished edges ready for installation.

The routing process requires careful speed and feed control. Too fast causes chipping and breakage. Too slow creates heat buildup that can crack the glass. Modern CNC systems use adaptive controls that adjust parameters based on glass type and tool condition.

Tool selection makes a huge difference in results. Diamond-coated bits last 10-20 times longer than carbide tools. The initial cost is higher, but the improved surface finish and extended life reduce overall processing costs.

Water cooling systems prevent overheating during machining. The coolant also removes glass particles that can scratch the surface. Some systems use air cooling for thin glass where water contact might cause problems.

Edge quality depends on spindle speed, feed rate, and tool geometry. High-speed spindles (up to 24,000 RPM) with slow feed rates produce the smoothest edges. Multiple finishing passes create optical-quality surfaces suitable for high-end applications.

| Operation | Tool Type | Spindle Speed | Feed Rate |

|---|---|---|---|

| Rough Cut | Diamond Wheel | 6,000 RPM | 2 m/min |

| Edge Polish | Diamond Bit | 18,000 RPM | 0.5 m/min |

| Hole Drilling | Core Drill | 3,000 RPM | 0.1 m/min |

| Profile Cut | Diamond Router | 12,000 RPM | 1 m/min |

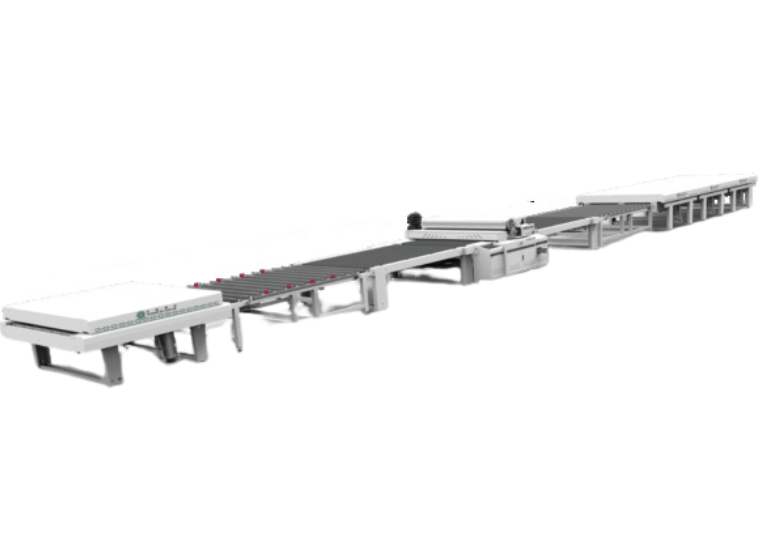

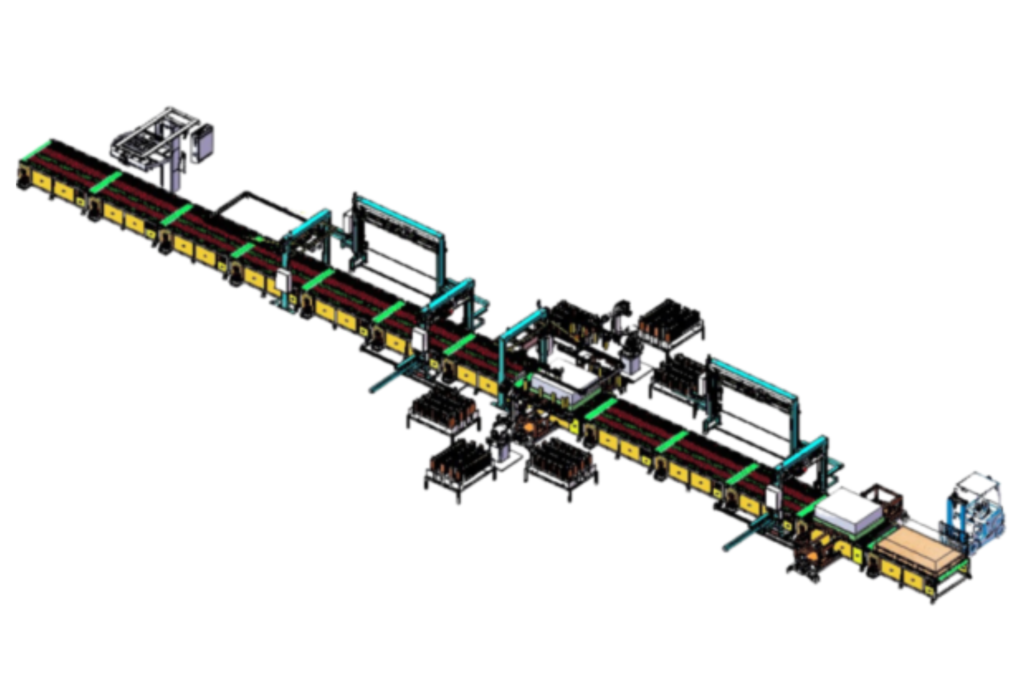

Which automated handling systems integrate with cutting equipment?

Automation reduces labor costs and improves safety around glass cutting operations. Robotic systems handle heavy glass panels that would require multiple workers.

Automated glass handling systems use vacuum lifters, conveyor systems, and robotic arms to move glass sheets weighing up to 2,000kg. They integrate with cutting machines to provide continuous operation, reduce breakage by 75%, and improve worker safety significantly.

Our experience with automated packing systems shows how proper handling reduces damage during processing. Glass manufacturers report 40-60% reduction in handling-related breakage after installing automated systems.

Vacuum lifting systems work well for flat glass sheets. The suction cups distribute load evenly across the glass surface. Multiple suction zones prevent flexing that can cause stress fractures in large panels.

Conveyor systems must handle glass weight while maintaining position accuracy. Air cushion tables support heavy glass panels while allowing precise positioning. The smooth surface prevents scratching during movement.

Integration between handling systems and cutting machines requires precise timing. The glass position must align with cutting head location within ±1mm tolerance. Advanced systems use laser measurement to verify position before cutting begins.

Safety features include emergency stops, light curtains, and redundant vacuum systems. Glass cutting operations involve sharp edges and heavy materials. Proper automation reduces worker exposure to these hazards while improving productivity.

Conclusion

The best glass cutting and routing machines combine precision, speed, and reliability to meet modern production demands while reducing waste and improving safety.