Greenhouse glass must optimize light transmission for plant growth. Reflection reduces efficiency, lowering crop yields. How do we ensure maximum light penetration while maintaining glass durability and energy efficiency?

Anti-reflective (AR) coating lines for greenhouse glass improve light transmission, reducing reflection losses by up to 8-10%. These coatings enhance plant growth, lower energy costs, and extend glass lifespan, making them essential for modern greenhouse operations.

Anti-reflective coating for greenhouse glass

Advancements in functional glass coatings allow for better greenhouse efficiency. Let’s explore how anti-reflective coating solutions can revolutionize agricultural glass applications.

Why does greenhouse glass need anti-reflective coatings?

Greenhouses depend on sunlight. But ordinary glass reflects 8-10% of incident light, reducing the amount available for plants. How can we fix this?

Anti-reflective coatings reduce reflection, increasing light transmission up to 98%. This enhances photosynthesis, promoting better plant health and higher yields. The result is improved agricultural productivity and energy savings.

Greenhouse glass with AR coating

How do anti-reflective coatings benefit greenhouse glass?

Anti-reflective coatings play a vital role in modern greenhouses. Let’s break down the advantages:

| Benefit | Impact on Greenhouse Efficiency |

|---|---|

| Increased light transmission | Boosts plant photosynthesis, improving crop growth |

| Reduced energy consumption | Enhances natural light use, lowering electricity costs |

| Improved weather resistance | Protects against UV degradation and chemical damage |

| Longer glass lifespan | Minimizes wear and tear, reducing replacement needs |

These advantages make AR-coated greenhouse glass a smart investment. But how do we apply these coatings effectively?

What technologies are used in anti-reflective coating lines?

Applying anti-reflective coatings requires precision and advanced technology. What are the best coating methods for greenhouse glass?

The most effective AR coating lines use vacuum deposition, dip-coating, or spray-coating techniques. These methods ensure uniformity, durability, and high transmission rates for greenhouse applications.

Greenhouse glass coating process

Key Anti-Reflective Coating Technologies

| Coating Method | Process | Advantages |

|---|---|---|

| Vacuum Deposition | Thin-film layers applied in a controlled vacuum | Best optical performance, highly durable |

| Dip Coating | Glass submerged in coating solution | Cost-effective, smooth application |

| Spray Coating | Fine mist sprayed onto glass surface | Quick application, scalable production |

Each method offers distinct advantages. Choosing the right one depends on production scale, cost, and required optical performance.

How does anti-reflective glass improve energy efficiency?

Greenhouses use artificial lighting and climate control systems. How does AR glass impact energy consumption?

AR-coated glass reduces energy costs by optimizing natural light use. This minimizes reliance on artificial lighting, improving energy efficiency and lowering operational expenses.

Energy-efficient greenhouse glass

Energy Savings with AR Coatings

| Energy Factor | Impact with AR Coating |

|---|---|

| Reduced lighting costs | More natural light, less artificial lighting needed |

| Lower heating needs | Improved solar gain, reducing heating expenses |

| Decreased cooling load | UV and IR control for better temperature regulation |

These benefits make anti-reflective coatings a key component in sustainable greenhouse design.

What are the best anti-reflective coating equipment solutions?

To achieve superior AR coatings, specialized equipment is necessary. What are the leading solutions available today?

Industrial AR coating lines, like those from Glass Coat, provide high-efficiency, scalable solutions for greenhouse glass production. These systems use precision engineering to ensure durability and optimal performance.

Industrial glass coating machine

Recommended AR Coating Equipment

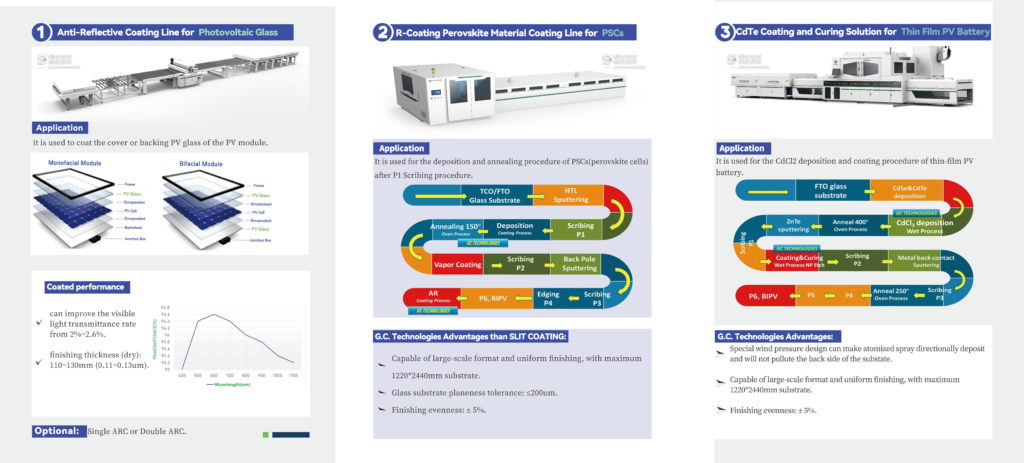

- Glass Coat Photovoltaic Glass ARC Line – Ideal for high-performance AR coatings on large-scale glass panels.

- Glass IR & UV Shading Coating Line – Balances anti-reflective properties with infrared and UV protection.

- Thin Film CdTe PV Technology – Advanced thin-film technology enhancing light transmission.

- Perovskite Material Coating Line – Next-generation coatings for energy-efficient glass solutions.

These systems help manufacturers produce high-performance greenhouse glass efficiently.

What future innovations are expected in anti-reflective coatings?

Glass coating technology is evolving. What trends will shape the future of AR coatings for greenhouses?

Emerging technologies, including nanostructured coatings and smart glass solutions, will further optimize light transmission, self-cleaning properties, and energy efficiency in agricultural glass applications.

Innovations to Watch

| Technology | Future Benefits |

|---|---|

| Nanostructured AR Coatings | Ultra-thin layers for maximum light transmission |

| Self-Cleaning Glass | Reduces maintenance and improves efficiency |

| Smart Adaptive Coatings | Adjusts light transmission based on conditions |

These developments will drive higher greenhouse productivity while reducing environmental impact.

Conclusion

Anti-reflective coatings are transforming greenhouse glass, maximizing light transmission and improving energy efficiency. With advanced coating solutions like Glass Coat’s ARC line, growers can achieve higher crop yields and reduced operational costs.

The future of greenhouse glass is clear—literally. Investing in high-quality anti-reflective coating lines ensures sustainability, productivity, and long-term profitability in modern agricultural production.