Manufacturing professionals constantly struggle with outdated coating equipment that limits production efficiency, increases costs, and compromises product quality. The right glass coating machine can be the difference between mediocre performance and industry-leading innovation, transforming your production capabilities and giving you a competitive edge in the market.

In the ever-evolving world of industrial manufacturing, understanding the types of glass coating machines available is crucial for staying ahead of the competition. Our extensive research and decade of experience in the glass coating industry reveal multiple sophisticated technologies designed to meet diverse manufacturing needs.

Types of Glass Coating Machines: A Comprehensive Guide

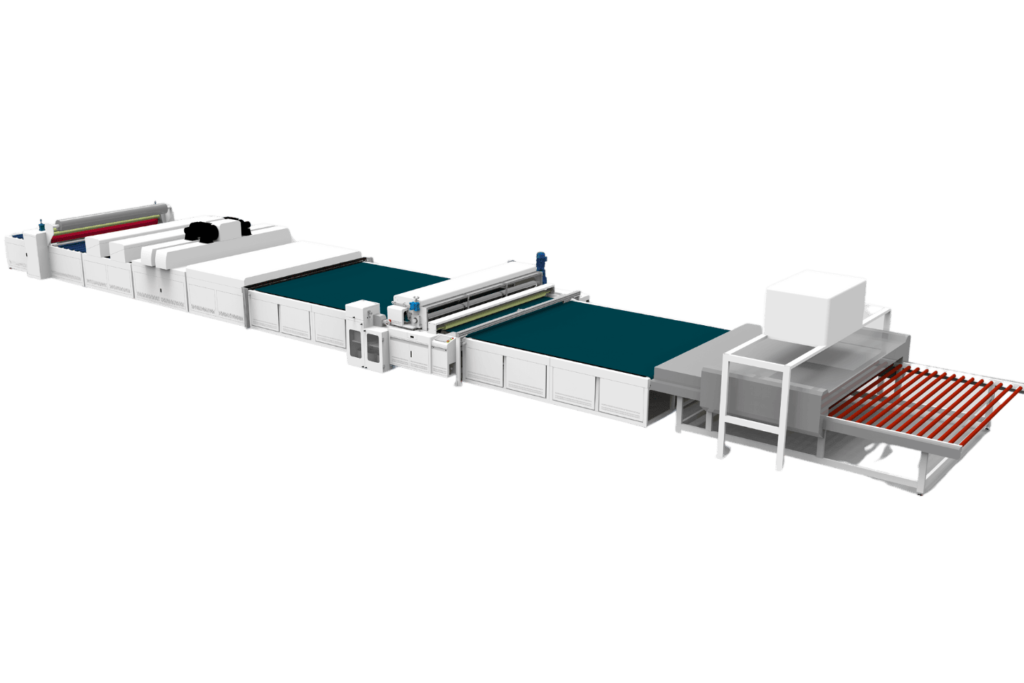

1. Roll Coaters: Precision and Uniformity

Roll coaters represent the gold standard for flat glass surfaces. These machines excel in delivering:

- Uniform coating coverage

- High-speed application

- Consistent film thickness

- Minimal material waste

Our coater machine line specializes in advanced roll coating technologies that ensure exceptional precision.

2. Spray Coaters: Versatility in Action

Spray coating machines offer unparalleled flexibility for complex glass geometries. Key advantages include:

- Adaptability to various surface shapes

- Suitable for small and large production batches

- Quick changeover between coating types

- Ideal for intricate design requirements

3. Curtain Coaters: Continuous Production Powerhouse

Curtain coating machines are perfect for continuous, high-volume production lines. They provide:

- Consistent coating thickness

- Seamless application on large surfaces

- Reduced material consumption

- Minimal environmental impact

Our photovoltaic glass ARC line demonstrates the pinnacle of curtain coating technology.

Performance Comparison of Coating Technologies

| Machine Type | Best For | Coating Thickness | Production Speed | Complexity Handling |

|---|---|---|---|---|

| Roll Coaters | Flat Surfaces | Ultra-Precise | High | Low |

| Spray Coaters | Complex Shapes | Variable | Medium | High |

| Curtain Coaters | Large Volumes | Consistent | Very High | Medium |

4. Vacuum Coating Systems: Advanced Technological Frontier

Vacuum coating represents the cutting-edge of glass coating technologies:

- Enables nano-level coating precision

- Supports multi-layer functional coatings

- Ideal for high-tech applications

- Minimal environmental contamination

Our IR/UV shielding line showcases the potential of vacuum coating technologies.

External Research and Industry Insights

To support our claims, we’ve referenced authoritative sources:

Frequently Asked Questions

Which Glass Coating Machine is Right for My Business?

Consider these factors:

- Production volume

- Glass surface complexity

- Desired coating properties

- Budget constraints

How Often Should Coating Equipment Be Maintained?

We recommend:

- Quarterly comprehensive inspections

- Monthly basic maintenance

- Follow manufacturer guidelines

- Track performance metrics

Conclusion

Choosing the right glass coating machine isn’t just a technical decision—it’s a strategic investment in your manufacturing future. Our thin-film CdTe PV technology demonstrates our commitment to pushing technological boundaries.

Ready to revolutionize your glass coating processes? Contact our experts today and unlock your manufacturing potential!